devops engineer resume filetype:pdf

DevOps Engineer Resume: A Comprehensive Guide (2026)

Today, February 27, 2026, DevOps blends development and operations, emphasizing automation, collaboration, and a cultural shift for faster, reliable software delivery․

The year 2026 marks a pivotal moment for DevOps, evolving beyond a methodology into a core organizational philosophy․ It’s no longer simply about bridging the gap between development and IT operations; it’s about fostering a collaborative culture where teams share ownership and responsibility throughout the entire software lifecycle․ This shift is driven by the increasing demand for rapid, continuous delivery of high-performance applications and services․

Key trends reshaping the DevOps landscape include the integration of Artificial Intelligence (AI) and automation, a heightened focus on cost control, and an unwavering commitment to security․ These forces are demanding DevOps engineers possess a broader skillset, encompassing not only traditional infrastructure management but also proficiency in AI/ML Ops and advanced automation scripting․ Successful DevOps implementation now directly impacts an organization’s ability to innovate and compete effectively in a dynamic market․

II․ Core DevOps Skills for Resumes

A competitive DevOps engineer resume in 2026 must showcase a robust skillset reflecting the evolving demands of the field․ Proficiency in automation tools – Ansible, Terraform, Puppet, and Chef – is paramount, demonstrating the ability to streamline infrastructure provisioning and configuration management․ Deep expertise in cloud platforms like AWS, Azure, and GCP is equally crucial, highlighting experience with cloud-native services and architectures․

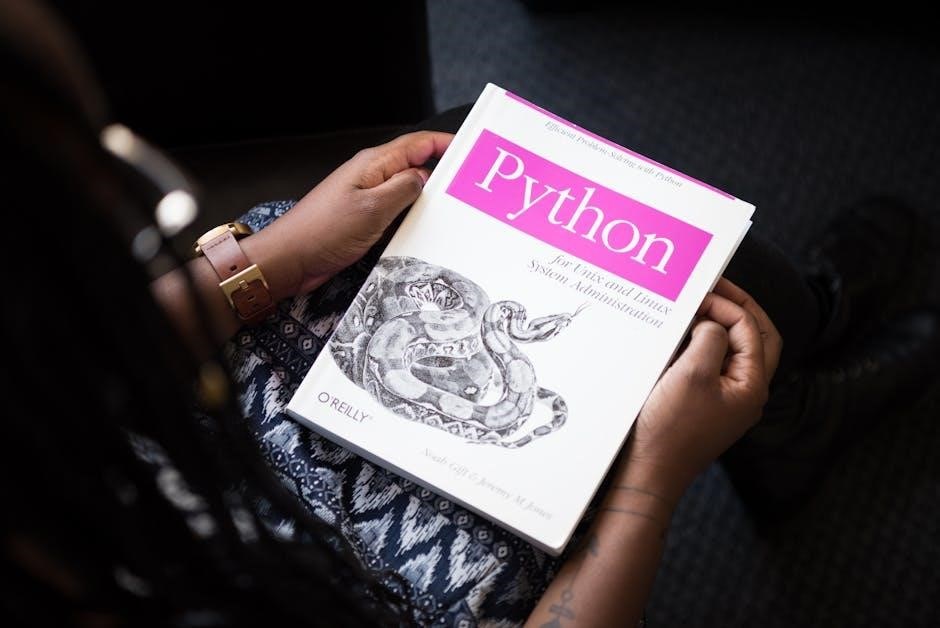

Furthermore, mastery of containerization technologies (Docker) and orchestration platforms (Kubernetes) is non-negotiable․ Employers seek candidates who can build, deploy, and manage scalable, resilient applications in containerized environments․ Beyond these technical skills, a strong understanding of CI/CD pipelines and experience with scripting languages like Python and Bash are highly valued․ Demonstrating a commitment to continuous learning and adaptation is essential for success․

A․ Automation Tools (Ansible, Terraform, Puppet, Chef)

Highlighting automation expertise is critical․ Ansible’s agentless architecture and YAML-based playbooks demonstrate infrastructure-as-code proficiency․ Terraform, with its declarative configuration language, showcases cloud infrastructure provisioning skills; Puppet and Chef, while established, still signal experience in configuration management and desired state enforcement․

Quantify your impact: “Automated infrastructure deployment, reducing provisioning time by 40% using Terraform․” Detail projects where you’ve used these tools to streamline processes, improve consistency, and reduce manual errors․ Mention specific modules or roles developed․ Employers value candidates who can not only use these tools but also extend their functionality․ Showcase scripting skills used in conjunction with these tools for enhanced automation capabilities․

B․ Cloud Platforms (AWS, Azure, GCP)

Demonstrate proficiency in major cloud providers․ AWS experience should highlight services like EC2, S3, IAM, and CloudFormation․ Azure skills should focus on Virtual Machines, Azure Storage, Azure DevOps, and ARM templates․ GCP expertise should showcase Compute Engine, Cloud Storage, Kubernetes Engine (GKE), and Deployment Manager․

Quantify your cloud impact: “Migrated on-premise infrastructure to AWS, resulting in a 25% cost reduction․” Detail projects involving cloud-native architectures, serverless computing, and infrastructure-as-code․ Certifications (AWS Certified DevOps Engineer, Azure DevOps Engineer Expert) are highly valuable․ Emphasize experience with cloud security best practices and compliance standards․ Showcase your ability to design, deploy, and manage scalable and resilient cloud solutions․

C․ Containerization & Orchestration (Docker, Kubernetes)

Highlight expertise in container technologies and orchestration platforms․ Showcase Docker skills – image creation, container lifecycle management, and Docker Compose․ Kubernetes experience is crucial; detail deployments, scaling, service discovery, and rolling updates․ Mention specific Kubernetes components like Pods, Deployments, Services, and Namespaces․

Quantify your impact: “Automated application deployments with Kubernetes, reducing release cycles by 40%․” Describe projects involving containerization of applications, microservices architectures, and CI/CD pipelines integrated with Kubernetes․ Certifications (Certified Kubernetes Administrator ⸺ CKA) are advantageous․ Emphasize experience with container security, networking, and storage․ Demonstrate your ability to manage and troubleshoot complex Kubernetes clusters․

III․ Resume Format & Structure

Choosing the right format is paramount for ATS compatibility and readability․ A combination resume is often ideal, blending chronological experience with a skills-focused section․ Prioritize clarity and conciseness; aim for a one to two-page document․ Use a clean, professional template․ Key sections include: Contact Information, Summary/Objective, Skills, Experience, Education, and Certifications․

Employ bullet points to detail accomplishments within each role․ Use action verbs to describe your contributions․ Ensure consistent formatting throughout․ Reverse-chronological order is standard for experience․ Tailor your resume to each job description, emphasizing relevant skills․ Proofread meticulously for errors in grammar and spelling․ Consider using a PDF format to preserve formatting across different systems․

A․ Chronological vs․ Functional vs․ Combination Formats

Chronological resumes list experience in reverse date order, highlighting career progression – best for stable career paths․ Functional resumes emphasize skills over work history, useful for career changers or those with gaps, but often disliked by ATS․ The combination format, often preferred for DevOps roles, balances both․

It showcases skills prominently while still providing a clear work history․ This approach allows recruiters to quickly identify relevant expertise (automation, cloud, containerization) and understand your career trajectory․ For experienced DevOps Engineers, a combination or chronological format is generally recommended․ Carefully consider your experience and the target job description when selecting a format․

B․ Key Resume Sections: Overview

A strong DevOps Engineer resume requires several key sections․ Begin with a concise Summary/Objective highlighting your core skills and career goals․ The Skills section is crucial, categorized for clarity (see section IV)․ A detailed Experience section (section V) should showcase quantifiable achievements and project-based descriptions․

Include an Education section listing relevant degrees and certifications (section VI)․ Don’t forget a section for Certifications, emphasizing AWS, Azure, or GCP credentials․ Tailor each section to the specific job description, incorporating relevant keywords (section VII)․ Prioritize clarity, conciseness, and quantifiable results to demonstrate your impact as a DevOps professional․

IV․ Skills Section: Highlighting DevOps Expertise

The Skills section is paramount for a DevOps Engineer resume․ Categorize your technical skills for easy readability: Automation Tools (Ansible, Terraform, Puppet, Chef), Cloud Platforms (AWS, Azure, GCP), and Containerization & Orchestration (Docker, Kubernetes)․

Beyond technical prowess, emphasize Soft Skills like collaboration and communication – essential for bridging Dev and Ops teams․ Showcase proficiency in scripting languages like Python and Bash, increasingly vital with AI/ML Ops integration (section VIII)․ Clearly demonstrate your ability to automate processes and contribute to a collaborative, efficient DevOps culture․ Quantify your skills whenever possible to demonstrate practical application․

A․ Technical Skills Categorization

Organizing technical skills is crucial for ATS readability and recruiter comprehension; Create distinct categories: Infrastructure as Code (Terraform, CloudFormation), Configuration Management (Ansible, Puppet, Chef), and Continuous Integration/Continuous Delivery (CI/CD) tools (Jenkins, GitLab CI, Azure DevOps)․

Further categorize by Cloud Proficiency (AWS, Azure, GCP – specify services used), Containerization (Docker, Podman), and Orchestration (Kubernetes, Docker Swarm)․ Don’t simply list; indicate proficiency level (e․g․, proficient, experienced, familiar)․ This structured approach highlights your breadth and depth of DevOps expertise, making your resume easily scannable and impactful․

B․ Soft Skills for DevOps Engineers (Collaboration, Communication)

DevOps thrives on teamwork; therefore, emphasize collaboration and communication skills․ Highlight experience working cross-functionally with development, operations, and QA teams․ Showcase your ability to facilitate meetings, resolve conflicts, and build consensus․

Demonstrate strong written and verbal communication skills – essential for documentation, incident reports, and knowledge sharing․ Mention experience with presenting technical information to both technical and non-technical audiences․ A DevOps engineer must champion a culture of shared ownership and continuous improvement, requiring excellent interpersonal abilities․ These ‘soft’ skills are increasingly vital in 2026․

V․ Experience Section: Demonstrating Impact

Your experience section should showcase quantifiable achievements, not just responsibilities․ Instead of stating “Managed Kubernetes clusters,” write “Reduced deployment time by 30% by automating Kubernetes cluster scaling with Terraform․” Focus on projects where you implemented DevOps practices․

Describe your role in automating infrastructure, streamlining CI/CD pipelines, and improving system reliability․ Use action verbs and metrics to demonstrate your impact․ Highlight experience with tools like Azure DevOps or similar platforms․ Frame descriptions around optimizing developer productivity and operational reliability – key tenets of DevOps in 2026․ Project-based descriptions are crucial for illustrating practical application․

A․ Quantifiable Achievements (e․g․, Reduced Deployment Time)

Demonstrate impact with numbers! Instead of saying “Improved CI/CD pipeline,” state “Reduced CI/CD pipeline execution time by 40% using parallelization and optimized testing strategies․” Focus on metrics like deployment frequency, lead time for changes, mean time to recovery (MTTR), and change failure rate․

Examples include: “Automated infrastructure provisioning, resulting in a 25% cost reduction in cloud resources,” or “Implemented monitoring and alerting, decreasing incident resolution time by 15%․” Quantify improvements in system stability, performance, and security․ These concrete results immediately grab a recruiter’s attention and prove your value as a DevOps engineer․

B․ Project-Based Descriptions (Focus on DevOps Implementation)

Frame your experience around projects showcasing DevOps principles․ Don’t just list tasks; detail your role in implementing DevOps practices․ For example, instead of “Managed Kubernetes cluster,” write “Led the migration of a monolithic application to a Kubernetes cluster, automating deployments with Helm and improving scalability by 30%․”

Describe the challenge, your solution utilizing DevOps tools (like Azure DevOps, Docker, Terraform), and the positive outcome․ Highlight collaboration with development and operations teams․ Emphasize how your work optimized productivity, reliability, and service quality․ Use action verbs and focus on the impact of your contributions to the overall software lifecycle․

VI․ Education & Certifications

Highlight relevant academic credentials, such as a Bachelor’s or Master’s degree in Computer Science, Software Engineering, or a related field․ Include the university name, degree type, and graduation date․ Beyond degrees, certifications are crucial in demonstrating specialized DevOps expertise․

Prioritize industry-recognized certifications like AWS Certified DevOps Engineer, Azure DevOps Engineer Expert, or similar credentials from Google Cloud Platform (GCP)․ List the certification name, issuing organization, and date obtained․ Continuous learning is vital; showcase any recent training or courses related to AI/ML Ops, automation scripting (Python, Bash), or emerging DevOps trends․ This section validates your commitment to professional development․

A․ Relevant Degrees (Computer Science, Software Engineering)

A strong educational foundation is key․ Employers often seek candidates with Bachelor’s degrees in Computer Science, Software Engineering, or closely related disciplines․ These programs provide a solid understanding of software development principles, operating systems, and networking – all essential for a DevOps role․

Master’s degrees can further enhance your profile, particularly those specializing in cloud computing, data science, or cybersecurity․ Clearly list your degree name, the university attended, and your graduation date․ If your degree isn’t directly related, emphasize relevant coursework or projects that demonstrate applicable skills․ A solid academic background signals your ability to learn and adapt to new technologies․

B․ Key DevOps Certifications (AWS Certified DevOps Engineer, Azure DevOps Engineer Expert)

Demonstrate expertise with industry-recognized certifications․ AWS Certified DevOps Engineer – Professional validates skills in automating and managing AWS environments․ The Azure DevOps Engineer Expert certification showcases proficiency in implementing DevOps practices using Azure services․ These credentials significantly boost your resume․

Other valuable certifications include those from Google Cloud Platform (GCP) and certifications related to Kubernetes (CKA, CKAD)․ List certifications prominently, including the issuing organization and date of completion․ Certifications prove your commitment to continuous learning and validate your practical skills, making you a more competitive candidate in the evolving DevOps landscape․

VII․ Keywords for Applicant Tracking Systems (ATS)

Optimize your resume for Applicant Tracking Systems (ATS)․ ATS scan resumes for specific keywords to identify qualified candidates․ Thoroughly analyze job descriptions to pinpoint relevant terms – think automation tools (Ansible, Terraform), cloud platforms (AWS, Azure, GCP), and containerization technologies (Docker, Kubernetes)․

Strategically incorporate these keywords throughout your resume, including the skills section, experience descriptions, and summary․ Avoid keyword stuffing; use them naturally within context․ Focus on both technical skills and soft skills like collaboration and communication․ Tailor your keyword usage to each specific job application for maximum impact, ensuring your resume reaches the hiring manager․

A․ Identifying Relevant Keywords from Job Descriptions

Keyword identification begins with meticulous job description analysis․ Scrutinize each posting for frequently mentioned technologies, tools, and methodologies․ Look beyond the obvious – consider variations of terms․ For example, “infrastructure as code” alongside “Terraform” or “CloudFormation․”

Prioritize keywords related to automation, cloud services, and containerization․ Note specific versions or certifications requested (e․g․, AWS Certified DevOps Engineer)․ Pay attention to required soft skills like “collaboration” and “communication․” Create a master list of potential keywords, then rank them based on frequency and relevance to your experience․ This targeted approach ensures your resume aligns with employer needs․

B․ Strategic Keyword Placement in Resume

Strategic keyword integration is crucial for ATS compatibility․ Naturally incorporate identified keywords throughout your resume – avoid keyword stuffing․ Prioritize placement within your skills section, experience descriptions, and summary/objective statement․ Use keywords within quantifiable achievements to demonstrate impact․ For instance, “Automated infrastructure deployment using Terraform, reducing deployment time by 30%․”

Vary keyword phrasing to avoid repetition․ Utilize synonyms and related terms․ Ensure keywords are contextually relevant to your responsibilities and accomplishments․ Tailor your resume for each application, adjusting keyword emphasis based on the specific job description․ This focused approach maximizes your resume’s visibility and increases your chances of landing an interview․

VIII․ Resume Optimization for 2026 Trends (AI & Automation Focus)

In 2026, AI, automation, cost control, and security dominate DevOps․ Highlight experience with AI/ML Ops, showcasing skills in model deployment, monitoring, and automation․ Emphasize proficiency in scripting languages like Python and Bash, crucial for automating tasks and infrastructure management․ Demonstrate experience with infrastructure-as-code tools like Terraform and Ansible, vital for automated provisioning․

Showcase contributions to cost optimization initiatives through automation and efficient resource utilization․ Security expertise is paramount; mention experience with DevSecOps practices and security automation tools․ Quantify achievements related to automation, such as reduced manual effort or faster release cycles․ Align your resume with these trends to demonstrate future-readiness․

A․ Highlighting AI/ML Ops Experience

As AI integration expands, showcasing AI/ML Ops experience is critical․ Detail involvement in the entire machine learning lifecycle – from model development and training to deployment and monitoring․ Specify experience with MLOps tools for continuous integration and continuous delivery (CI/CD) of machine learning models․ Highlight skills in containerizing models using Docker and orchestrating them with Kubernetes for scalable deployments․

Emphasize experience with model versioning, data validation, and automated testing of ML pipelines․ Mention any work with cloud-based ML services (AWS SageMaker, Azure Machine Learning, GCP Vertex AI)․ Quantify achievements, such as reduced model deployment time or improved model accuracy through automated retraining․ Demonstrating a proactive approach to AI/ML infrastructure is key․

B․ Demonstrating Automation Scripting Skills (Python, Bash)

Automation is foundational to DevOps; therefore, prominently display scripting proficiency․ Specifically mention Python and Bash, as these are industry standards for automating tasks․ Detail projects where you’ve used scripting to automate infrastructure provisioning, configuration management, or application deployments․ Showcase experience with scripting for CI/CD pipelines, including build automation and automated testing․

Provide concrete examples of scripts developed – for instance, automating server scaling, log analysis, or security patching․ Highlight any experience with infrastructure-as-code tools like Terraform or Ansible, where scripting is essential․ Quantify the impact of your scripting efforts, such as reduced manual effort or improved system reliability․ Demonstrating practical scripting skills is highly valued in 2026․